Rotor-Equivalent-Wind-Speed

A turbine manufacturer’s power curve assumes a standard shear profile across the rotor disk. For a constant shear, the energy across the rotor is fairly constant with changing values of the shear exponent. However, when shear changes part way through the rotor, this generally results in much larger variations in the overall energy across the rotor.

Extreme real-world cases of non-standard shear include situations in which the shear drops off above hub height or even reverses completely, leading to a nose in the wind speed profile part way between the lower and upper tips of the turbine rotor.

In order to be able to assess the significance of the effect of non-standard shear on energy capture, the industry has come up with proposed changes that include a simple method to compare non-standard shear situations to that assumed in the power curve. This method splits the rotor into several vertical slices, taking the measured wind speed at each height and comparing to the standard case to come up with a correction factor in the following manner.

Split the rotor up into a number of horizontal slices which can be determined by the user (>14 is recommended)

Calculate the area and centre height for each slice

Calculate a profile based on the wind speed at hub height and a constant shear of 0.2 say so that we have velocities at the centre of each slice

Query the met mast multi-height data so that we have velocities at the centre of each slice

For both the sheared and measured profile, take the fractional area of each slice and multiply it by the wind speed at the centre of that slice cubed and sum them before taking the cube root

Call these numbers Vshear and Vdata

The rotor equivalent wind speed is then the hub height wind speed multiplied by the ratio Vdata/Vshear

The rotor equivalent wind speed is then used in the calculation of the gross, array and net energies.

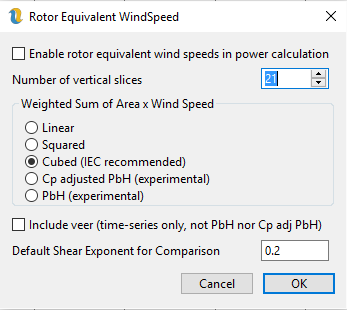

Figure 151: Rotor Equivalent Wind Speed Settings

In order to enable rotor equivalent wind speed, it needs to be checked in the rotor equivalent wind speed settings above as well as for each turbine type for which you want to use rotor equivalent wind speed.